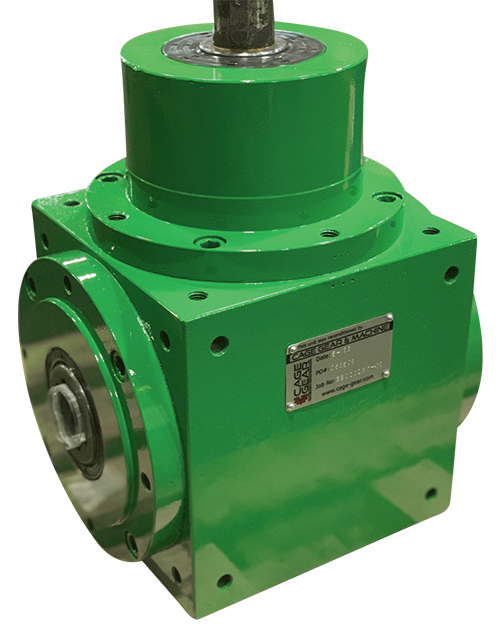

The Cage Gear team of highly skilled craftsmen and engineers are recognized as the leading gearbox repair specialists.

Benefits Of Gearbox Repair At Cage Gear

- Gearbox refurbishment up to 25 tons

- On-site reverse engineering, can provide drawings

- In-house gear manufacturing, minimal outsourcing, faster lead times

- Free pick up

- Free estimates returning to OEM operating condition accompanied with detailed inspection report

- All units rebuilt with highest quality bearings and seals

- All units sandblasted, painted, and packaged for long-term storage preservation (if needed)

- Conduct no-load spin test on all units prior to shipment

- 1-year warranty

- Emergency service 24/7

Gearbox Repair Services from Cage Gear

Over time, gearboxes require repairs due to wear and tear, improper maintenance, or even external damage. Gearbox repair can be a complex process that requires the expertise of professionals with the right equipment and knowledge to ensure that the gearbox is functioning optimally and safely. At Cage Gear we have the knowledge, tools, and expertise to return your gearbox to like new condition.

When to Repair a Gearbox

Gearboxes are designed to last for a long time, but they can develop problems that require repairs. Here are some signs that indicate that your gearbox needs repair:

Unusual Noise: If you notice a grinding or whining noise coming from the gearbox, it is a sign that something is wrong. The noise could be caused by worn-out gears or bearings, or other problems that require repair.

Leaking Oil: Gearboxes are filled with oil that lubricates the moving parts and cools the gears. If you notice oil leaking from the gearbox, it is an indication of a problem. The leak could be caused by worn-out seals or damaged gaskets, which need to be replaced.

Vibration: If you notice unusual vibrations coming from the gearbox or the machine itself, it is an indication that there is a problem. The vibration could be caused by worn-out bearings or gears that require repair.

Common Gearbox Problems

Gearboxes can develop a wide range of problems that require repair. Here are some of the most common gearbox problems:

Worn-out Gears: Over time, the gears in the gearbox can wear out due to normal use. When the gears are worn out, they can produce a grinding noise, which is an indication that they need to be replaced.

Leaking Oil: Oil leakage is a common problem with gearboxes. The leak could be caused by worn-out seals or damaged gaskets, which need to be replaced.

Bearing Failure: Bearings are essential components of the gearbox that allow the gears to rotate smoothly. When the bearings are worn out, they can produce a whining noise, which is an indication that they need to be replaced.

The Repair Process

The gearbox repair process can vary depending on the type of gearbox and the specific problem. Here are the general steps involved in gearbox repair:

Inspection: The first step in gearbox repair is to inspect the gearbox thoroughly to determine the cause of the problem. This involves disassembling the gearbox and examining the individual components.

Cleaning: Once the problem has been identified, the gearbox is cleaned thoroughly to remove any dirt, debris, or metal shavings that may be present.

Replacement of Components: The worn-out or damaged components are then replaced with new ones. This may include gears, bearings, seals, gaskets, or other components.

Reassembly: Once the new components have been installed, the gearbox is reassembled carefully, ensuring that all components are properly aligned and tightened.

Testing: The final step in gearbox repair is to test the gearbox to ensure that it is functioning correctly. This involves running the gearbox at different speeds and loads to ensure that it is working properly and without any unusual

The availability of replacement parts is another factor to consider when deciding whether to repair a gearbox. If the parts needed for the repair are readily available, a repair with OEM parts may be a simple option. However, if the parts are scarce or obsolete, Cage Gear can manufacture custom parts with technical precision and remarkably quick turnaround times.