The Repair Process

The gearbox repair process can vary depending on the type of gearbox and the specific problem. Here are the general steps involved in gearbox repair:

Inspection: The first step in gearbox repair is to inspect the gearbox thoroughly to determine the cause of the problem. This involves disassembling the gearbox and examining the individual components.

Cleaning: Once the problem has been identified, the gearbox is cleaned thoroughly to remove any dirt, debris, or metal shavings that may be present.

Replacement of Components: The worn-out or damaged components are then replaced with new ones. This may include gears, bearings, seals, gaskets, or other components.

Reassembly: Once the new components have been installed, the gearbox is reassembled carefully, ensuring that all components are properly aligned and tightened.

Testing: The final step in gearbox repair is to test the gearbox to ensure that it is functioning correctly. This involves running the gearbox at different speeds and loads to ensure that it is working properly and without any unusual

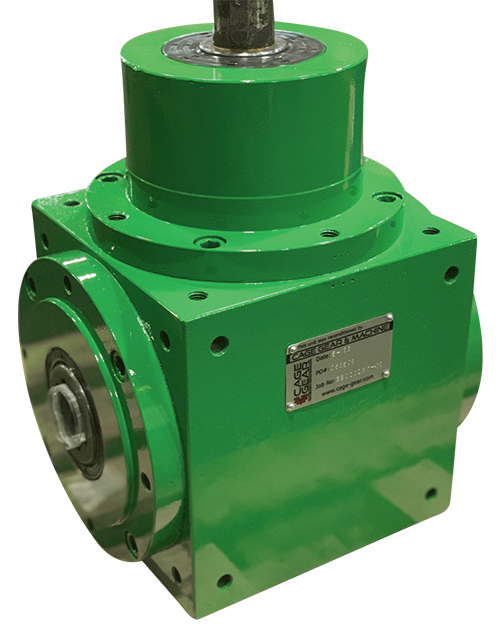

The availability of replacement parts is another factor to consider when deciding whether to repair a gearbox. If the parts needed for the repair are readily available, a repair with OEM parts may be a simple option. However, if the parts are scarce or obsolete, Cage Gear can manufacture custom parts with technical precision and remarkably quick turnaround times.